Pearlescent pigments are widely celebrated for their shimmering, iridescent qualities, but when it comes to outdoor applications, their ability to withstand the elements is just as crucial. Whether used in automotive finishes, exterior coatings, or consumer goods, understanding the key properties that contribute to the weather resistance of pearlescent pigments is essential for ensuring their long-term durability and visual appeal. So, what makes these pigments resilient to the harsh realities of outdoor environments like UV radiation, extreme temperatures, and humidity?

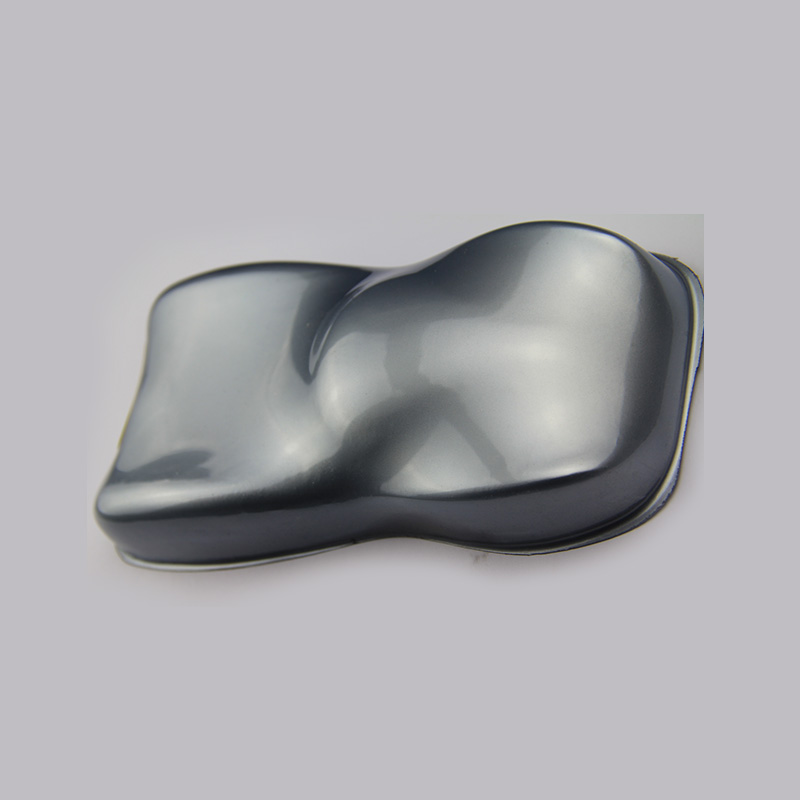

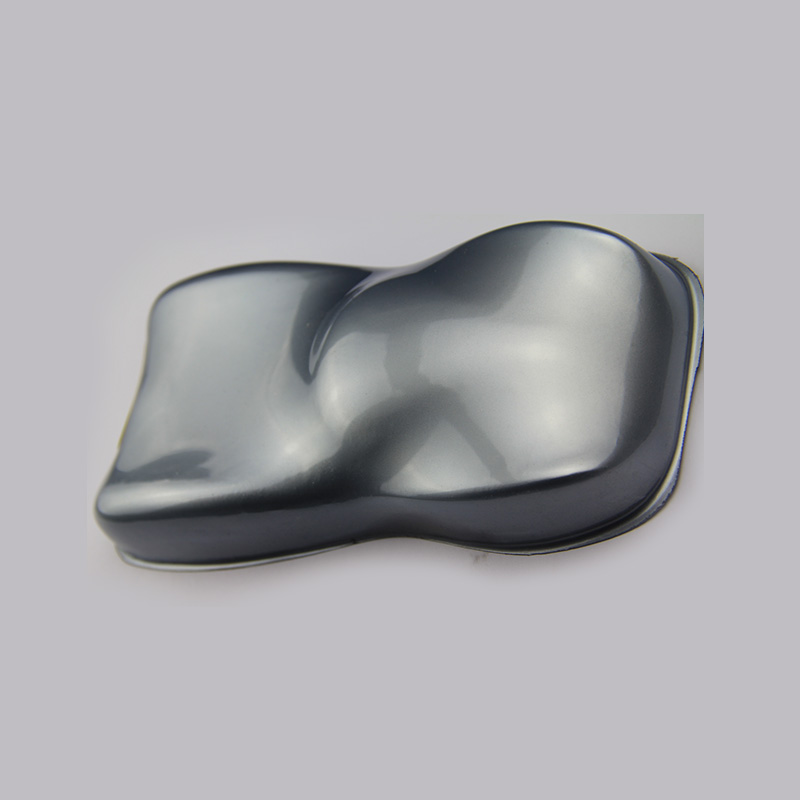

The ultimate factor in the weather resistance of pearlescent pigments lies in their composition. Pearlescent pigments typically consist of mica or glass flakes coated with metal oxide layers such as titanium dioxide or iron oxide. These coatings are integral to the pigment’s iridescence, but they also serve as a shield against environmental degradation. Titanium dioxide, for instance, is known for its strong UV-blocking properties, protecting the underlying mica or glass particles from sun damage. This not only prevents fading but also ensures that the color shift and shimmer effects remain vibrant and consistent over time. Similarly, the metal oxide layers act as barriers to moisture and pollutants, reducing the likelihood of discoloration or corrosion caused by environmental exposure.

However, the performance of pearlescent pigments doesn't rely solely on their inherent materials. The binder system used to hold the pigment particles together in a coating plays a pivotal role in weather resistance. High-quality binders—whether they are acrylic, polyurethane, or epoxy-based—ensure that the pigments stay securely adhered to the substrate, preventing them from being washed away or deteriorating under rain, snow, or humidity. These binders also provide the necessary flexibility to withstand temperature fluctuations and mechanical stresses, further enhancing the pigment's longevity. When paired with advanced surface treatments or coatings, such as UV-stable resins or hydrophobic layers, pearlescent pigments can achieve even greater resistance to the elements, protecting their shimmer and integrity under more extreme conditions.

Another important factor is the particle size and shape of the Weather Resistance Pearlescent Pigments themselves. Finer particles often exhibit a more intense sheen, but they can be more vulnerable to abrasion and environmental wear. Larger, more robust particles, on the other hand, tend to provide more durability and better weather resistance, as they are less likely to break down under the effects of wind, rain, or prolonged UV exposure. Spherical or flattened particles, which are often used in coatings for vehicles and industrial products, offer additional mechanical strength, helping the pigments resist impact and other forms of physical damage that could degrade their appearance.

Testing standards are another critical element in understanding the true weather resistance of pearlescent pigments. Advanced weathering tests, such as accelerated UV exposure (QUV) or Xenon Arc testing, simulate the prolonged effects of sunlight, moisture, and temperature cycles on pigments. These tests help manufacturers assess how well their pearlescent pigments hold up under real-world conditions and make adjustments to their formulations if needed. Notably, pigments that can pass these rigorous tests without significant fading, cracking, or loss of iridescence are considered top-tier for outdoor use.

While pearlescent pigments offer remarkable visual effects, their true strength lies in their ability to resist the forces of nature. The combination of UV-resistant metal oxides, protective binders, and durable particle designs creates a pigment that not only dazzles with color but stands the test of time, maintaining its beauty in the face of wind, rain, and sun. So, whether you're designing a new car finish or choosing pigments for an outdoor sculpture, the key properties of weather resistance are what will ultimately ensure your pearlescent products retain their luster and brilliance for years to come.