Zhejiang Coloray Technology Development Co., Ltd. is reliable China Rayshine Silver Coated Pearlescent Pigment supplier and Rayshine Silver Coated Pearlescent Pigment company , factory was founded in 2008, focusing on the research and development of cosmetic grade effect pigment for more than 10 years, The company has won many awards, including high-tech enterprise, provincial science and technology enterprise, provincial research and development center, provincial intelligent factory, etc. In 2017, the company was listed on KOSDAQ (stock code: 900310).

The company is located in the national high-tech industrial park - Deqing Moganshan High-tech Zone. In the core circle of the Yangtze River Delta economic zone, which is a pleasant city with a geographical location and beautiful natural environment, once selected by the New York Times as the eighteenth place in the world worth visiting. Coloray's factory is located in the picturesque Moganshan High-Tech Zone in Deqing, where we are making beautiful colors.

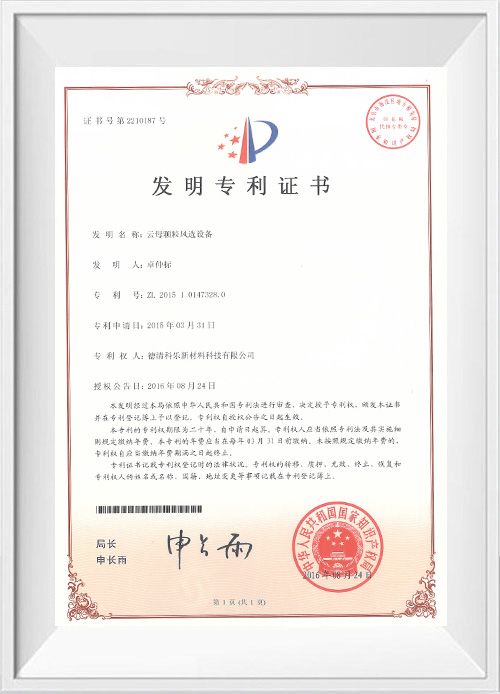

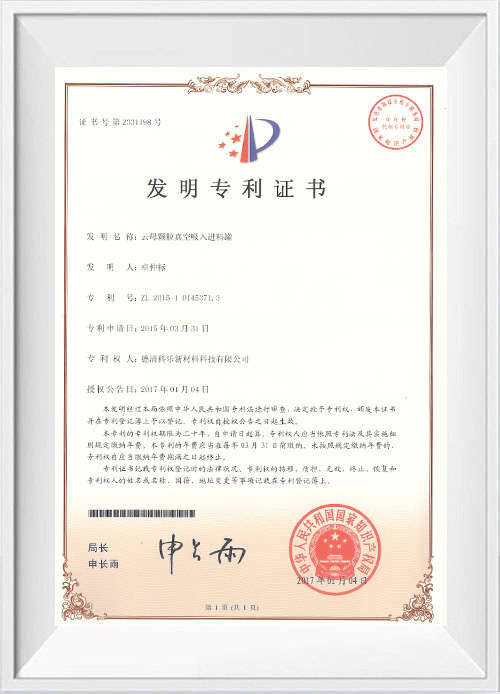

At the same time, the company adheres to the concept of innovation, and technological innovation is an inexhaustible driving force for enterprises. The company has cumulatively developed more than a thousand kinds of cosmetic-grade products. To continuously improve its R&D capability and innovation ability, the company has established industry-academia-research cooperation with major universities and introduced a large number of domestic and foreign high-end talents.

Coloray is committed to providing color users with a range of effects pigments with outstanding performance, stability, and batch consistency; Have professional technical support and price competitiveness. Whether it is cosmetics, coatings, plastics, printing inks, leather, or the construction industry, Coloray is a supplier and long-term partner of many international brands, ensuring consistent quality and unique results. Whether selecting a current product from our product manual or seeking a customized service, please contact us. Our experienced team will do our best to meet your requirements and satisfy you. With quality, strong technical support, and comprehensive services, Coloray is your partner. We also wholesale custom

Rayshine Silver Coated Pearlescent Pigment

Recently, Zhejiang Coloray Technology Development Co., Ltd., in collaboration with Changzhou University and other institutions, successfully completed...

READ MORE